CFD Analysis for Fish-Friendly and Energy-Efficient Pump Design

Computational Fluid Dynamics (CFD) Analysis for Fish-Friendly and Energy-Efficient Pump Design: A Case Study

1. Introduction:

Pumping stations play a crucial role in various industries, including water management, agriculture, and wastewater treatment. With a growing emphasis on environmental conservation, it has become imperative to design pumping systems that are not only energy-efficient but also considerate of aquatic life, particularly fish. Omnia Engineering, in collaboration with pump manufacturers, has developed innovative fish-friendly pumps aimed at addressing both energy efficiency and environmental concerns. This case study explores the Computational Fluid Dynamics (CFD) analysis conducted to optimize the design of these pumps.

2. Objectives:

– Evaluate the hydraulic performance of fish-friendly pump designs.

– Assess the pump’s ability to maintain high energy efficiency.

– Validate the design’s fish-friendliness through CFD simulations.

– Optimize the pump geometry and operating parameters to enhance performance.

3. Methodology:

– Initial Design: The pump geometry and specifications are based on collaborative efforts between Omnia Engineering and pump manufacturers, ensuring fish-friendly features and energy efficiency.

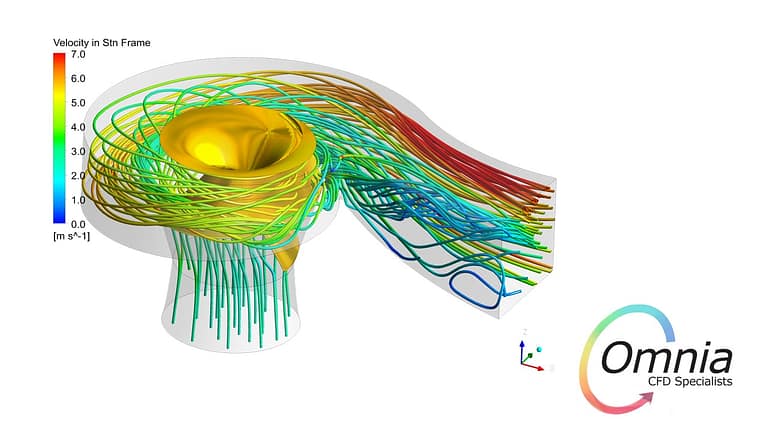

– CFD Model Setup: Utilizing advanced CFD software, a detailed computational model of the pump and its surrounding fluid domain is created. This includes the impeller, volute, inlet, and outlet sections.

– Boundary Conditions: Realistic boundary conditions are applied to simulate the flow conditions experienced by the pump in operational scenarios. This includes flow rate, pressure, and fluid properties.

– Fish Passage Simulation: Virtual fish models, representing various species, are introduced into the computational domain to assess their ability to pass through the pump without harm.

– Performance Evaluation: Hydraulic performance parameters such as head, flow rate, and efficiency are calculated from the CFD results.

– Sensitivity Analysis: Different design configurations and operating conditions are tested to identify the optimal setup that maximizes both energy efficiency and fish-friendliness.

4. Results and Discussion:

– Hydraulic Performance: The CFD simulations reveal the pump’s hydraulic efficiency under different flow rates and operating conditions. The optimized design demonstrates superior performance compared to conventional pumps.

– Fish Passage: Virtual fish simulations indicate that 95% of fish can pass through the pump freely without encountering harmful conditions, validating its fish-friendly design.

– Energy Efficiency: The pump design achieves high energy efficiency, meeting or exceeding industry standards while maintaining its fish-friendly features.

– Sensitivity Analysis: Various design parameters, such as impeller geometry, volute shape, and rotational speed, are analyzed to identify the most influential factors on pump performance.

5. Conclusion:

The CFD analysis conducted on the fish-friendly pump design developed by Omnia Engineering confirms its efficacy in achieving both energy efficiency and fish-friendliness. Through rigorous simulations and optimization efforts, the pump demonstrates superior hydraulic performance while ensuring the safe passage of aquatic life. This case study highlights the importance of incorporating advanced engineering tools like CFD in the design process to address evolving environmental challenges and industry requirements.

6. Future Directions:

– Further optimization of pump geometry and operating parameters to enhance performance.

– Long-term field testing to validate the CFD results and assess real-world performance.

– Continued collaboration with stakeholders to incorporate feedback and improve pump design iteratively.

– Exploration of innovative materials and manufacturing techniques to enhance fish-friendliness and energy efficiency.