CFD Analysis of Heat Exchanger

Many materials must have a lifespan of many years. To guarantee this, material tests are necessary. However, tests that span many years are impractical. Therefore, these tests are performed at elevated temperatures, allowing them to be conducted within a matter of days.

Omnia Engineering has developed a test system that allows the elevated temperature to be adjusted consistently, uniformly, and accurately. As a result, tests were performed successfully.

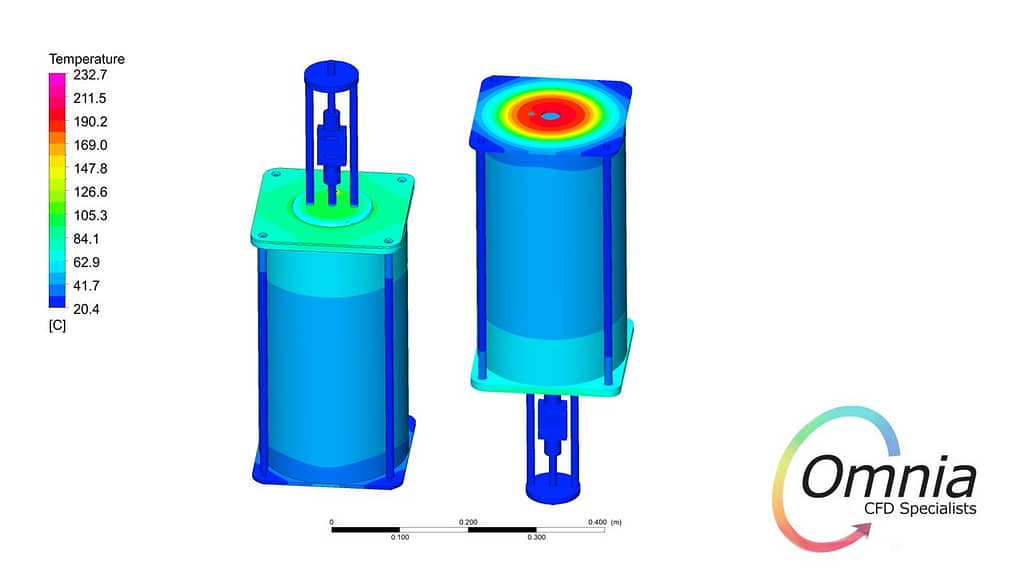

To optimize the testing process, Omnia Engineering implemented a Computational Fluid Dynamics (CFD) simulation. This simulation was meticulously set up to replicate the thermal environment of the test system. Key parameters such as airflow, heat distribution, and material properties were precisely modeled to ensure the accuracy of the simulation. The CFD simulation allowed for the fine-tuning of temperature control and the identification of any potential hotspots or areas of uneven heating.

The results from the CFD simulation were then validated against experimental data, confirming the reliability and precision of the test system. The ability to simulate and predict the thermal behavior of the materials under test conditions provided invaluable insights and helped in enhancing the overall test methodology.

The client was satisfied with the outcomes of both the physical tests and the CFD simulation. They appreciated the detailed and accurate control over the testing conditions, which assured them of the long-term reliability of their materials.